Hempcrete Building Blocks with Biochar, Hurd and Lime at Utopia Hemp

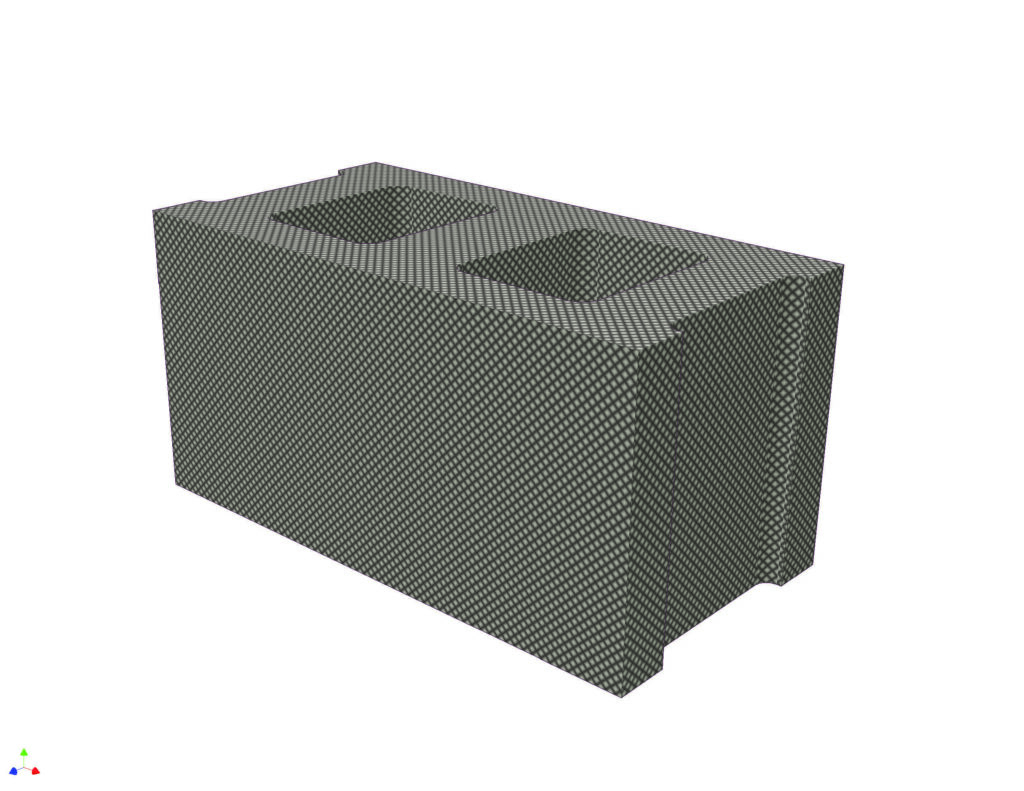

Hempcrete Building Blocks are made with spheroidal Biochar BB sized particles reinforcing the lime bound morphology of cast cement building blocks. Presented here is a process and machinery that blends “Biochar BB ‘s” with lime and water on demand.

Traditional block sizes and types are maintained with the mold geometry changes providing various sizes and types of traditional time proven and building code approved building blocks. There are no inserts or internal skeletal structures of any kind holding this block together.

The “Biochar BB’s” distribute firmly in the wet slurry due to their extreme light weight. They disperse evenly throughout the wet lime slurry during blending and bond with the lime when cured and set.

Biochar adheres positively with lime forming a carbon-calcium composite bonded matrix that outperforms the conventional cement building block morphology in terms of structural strength and R value..

They provide up to a 25% increase in structural strength and impact resistance however, the added value is in the energy savings over time with thermal insulation improvement of approximately 15% or better..

All Rights Reserved, ca: 2024 All inquiries welcome.

Building Code Compliant Block Manufacturing

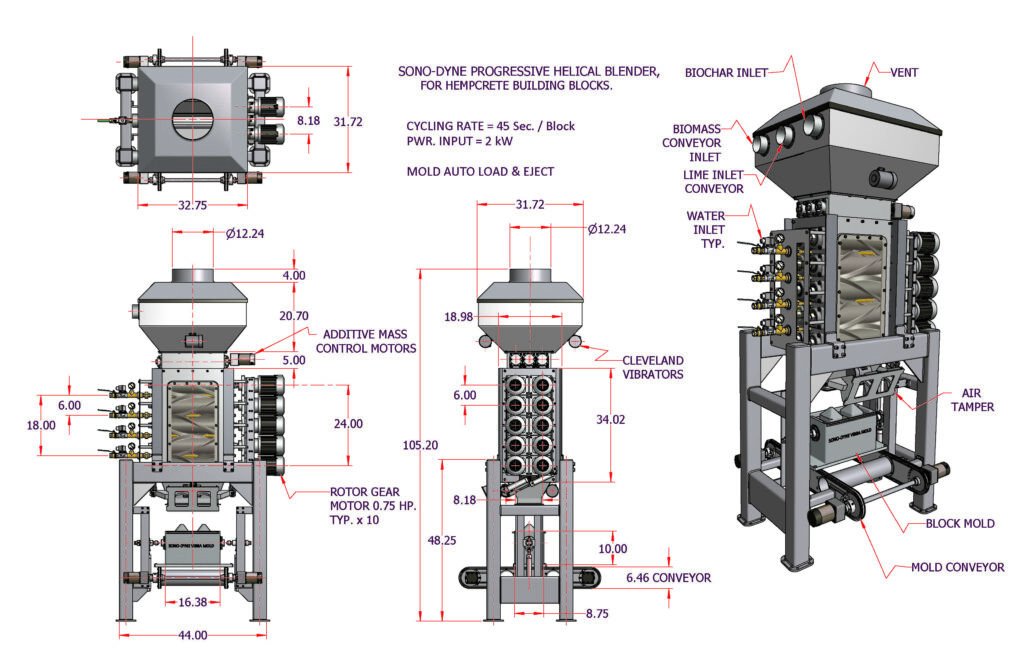

The machinery shown here comprises the initial mold positioning and filling station.

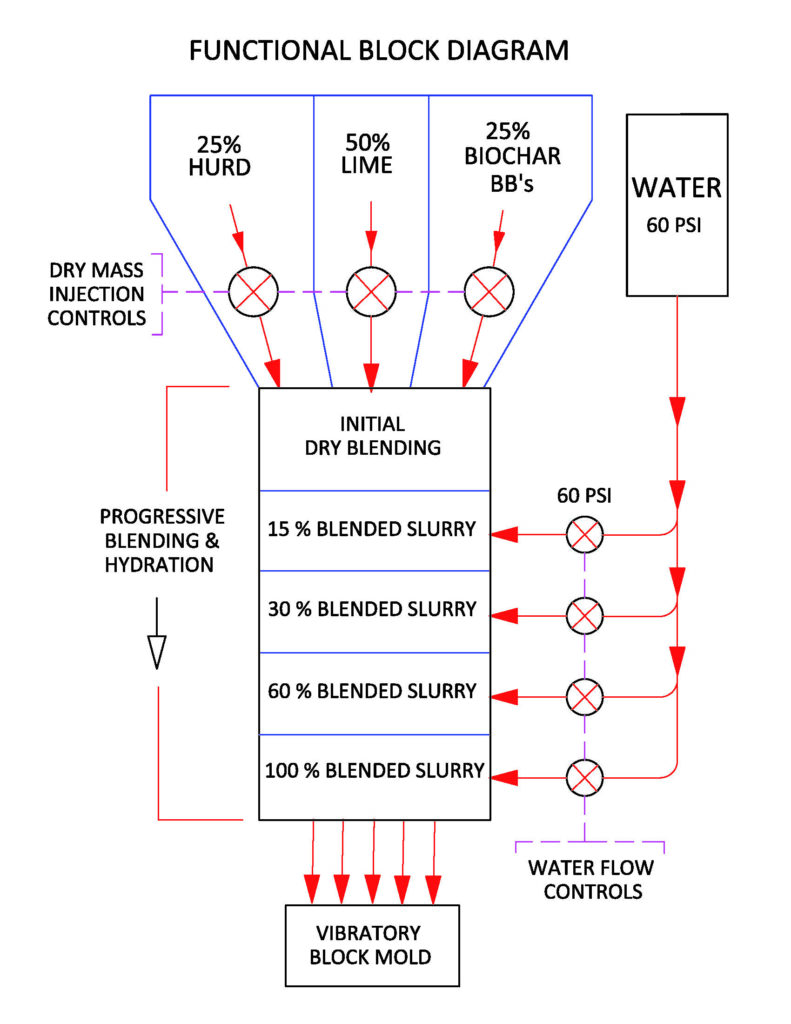

This novel approach adds water in four progressive mixing stages after initial dry blending of the constituent materials and allows controlling the rate of hydration to produce a block that is both stronger and having a higher R value over existing technology.

The dry constituent materials are blended into a slurry progressively as water is injected and finally mixed into a slurry with the right density just prior to mold filling.

Each rotor has 0.75 HP of power available to it spinning at about 200 RPM. The interior of the machine is totally washable from the inside after a duty cycle.

The helically splined rotors shown here are 18″ long x 6″ in diameter. They are extremely efficient in diffusing particulate solids into a homogenous blended morphology with the increased surface area provided by the helical geometry..

The blending kinetics are equally aggressive in each subsequent vertical blending stage thus providing matrix uniformity and consistent high quality raw material for the cast block.

The Helical Rotors are fabricated as mild steel weldments in both R.H. and L.H. so the splines can mesh with adjacent complementary rotors as shown.

Helical splines have significant increased surface contact areas providing more aggressive shearing forces to produce an aqueous slurry of multiple ingredients of varying densities.

The rotors are 8″ in diameter and 18″ long. They provide a homogenous mixture prior to and during hydration then are dropped into the mold as a slurry.

Three helical splines provide superior blending kinetics for a homogenous morphology.

A fabrication fixture is available on a different post on this site for the manufacture of this unique blending rotor.

This machinery is available for manufacture with full engineering shop CAD drawings and IP license..