Electro-Magnetic Exposure of Gold Ore Increases Au + Ag Recovery

An Electro-Magnetic method of generating microscopic fractures and fissures into the silica substrate of gold ores having some residual iron embedded therein has been validated at Barrick Gold. The iron particles in gold ore when exposed to an Electro-Magnetic field, generate stress and strain in the proximal silica for a significant increase of lixiviant uptake thus increasing gold recovery with the Merrill Crowe process.

All Rights Reserved ca, 2012

Barrick Gold Lab results shows a 10 to 17% gold recovery improvement over baseline after cyanidation in a 3 day cyanide bottle roll assay done in Barrick Gold’s labs back in 2011 – 2013 in Vancouver BC.

Silver yield also increased from 3% baseline to 9% in the samples tested. Barrick Gold was looking for a 20% increase minimum for their silver yield in their “Unlock the Value” program.

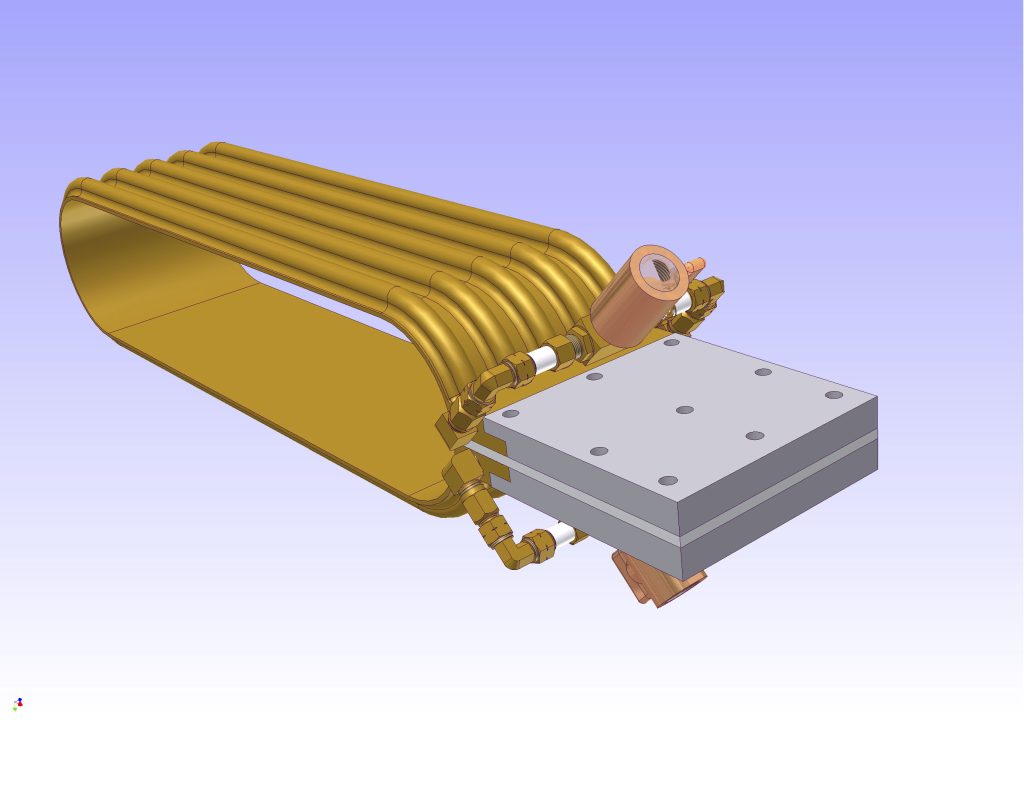

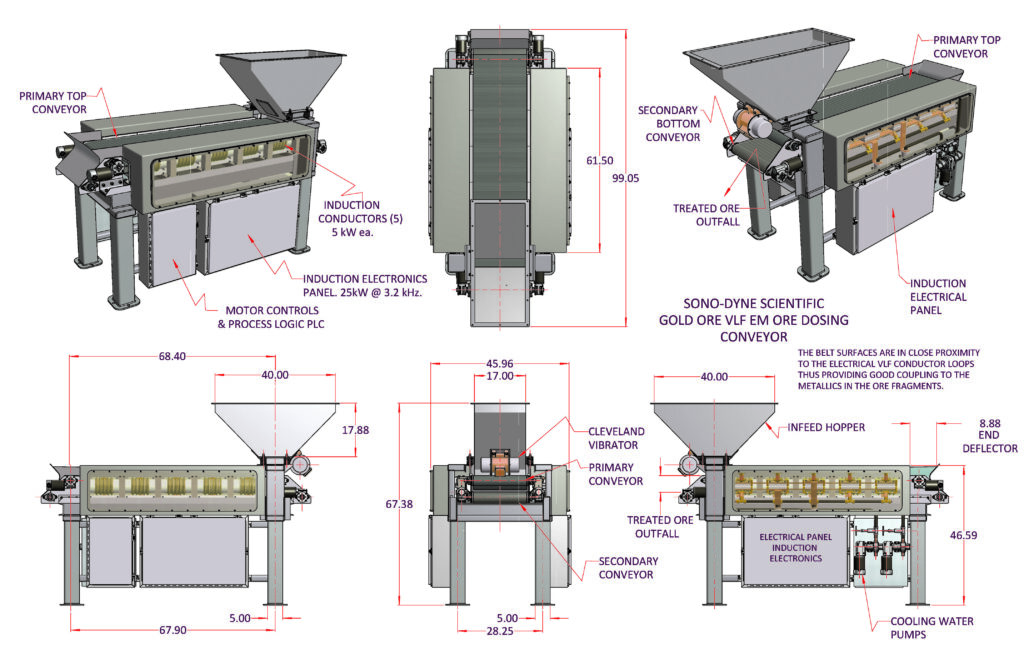

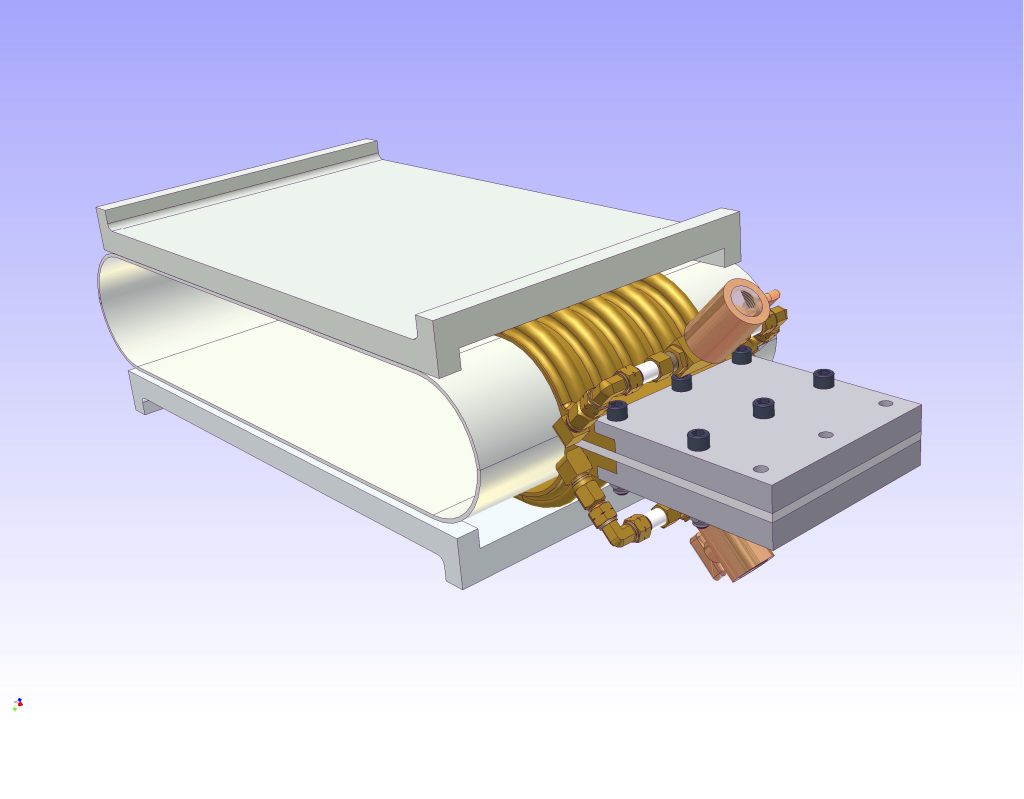

The electronics driving these induction modules is readily available on the commercial market to drive the EM conductor coils as shown. Cooling tubing is silver soldered to the flat copper conductor. This arrangement is easily capable of dissipating 10 kW of power at up to 330 kHz. of frequency,

.

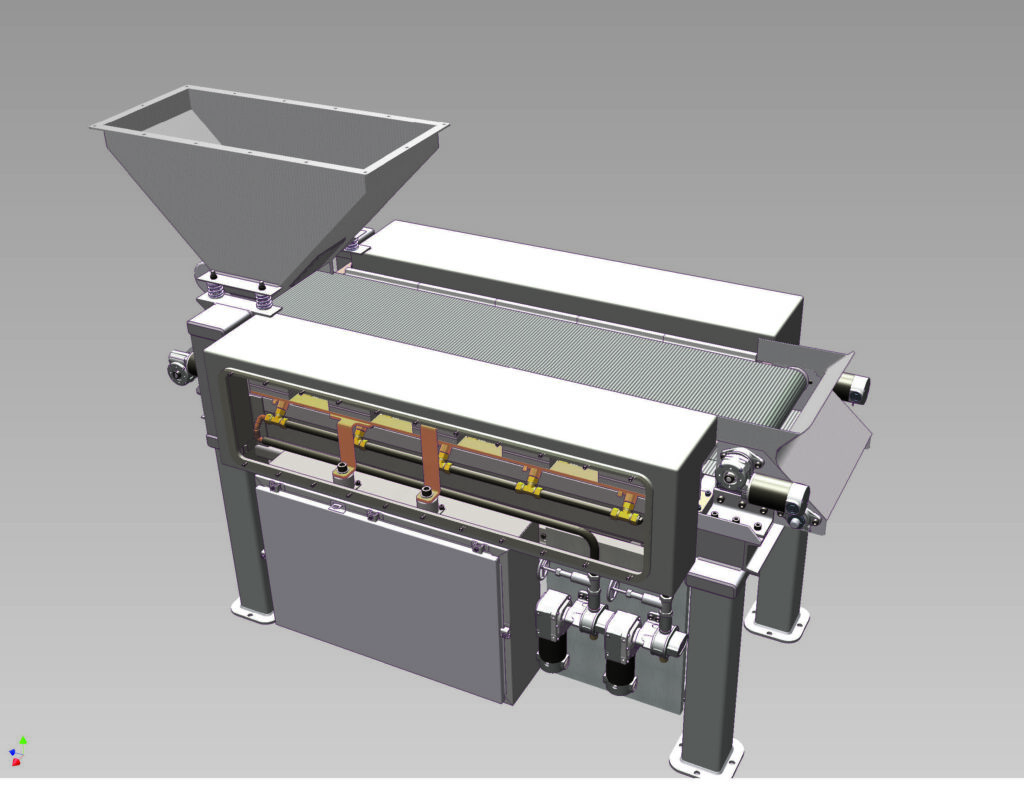

Two counter-rotating conveyor belts, over and under, provide a dual exposure of the ore fragments to the EM field generated by a plurality of flat copper coils through which the belts pass.

This novel method increases residence time in the EM field the gold ore encounters as they pass through in an arrangement whereby the residence time of the ore in the EM field is twice that of a machine of any length.

All rights are reserved to Edward Melcarek and Steven Duncombe c/o Sono-Dyne Scientific in priori and proviso.

Gold ore samples from their Valedero mine in Argentina were irradiated at Tocco Magnathermic in Detroit with their induction equipment then tested in Barrick Gold Technology Labs in Vancouver BC. in 2011

Induction modules stack together lengthwise and provide pathways for the conveyor belts carrying the gold ore fragments thereupon. The parts surrounding the coil are made from HDPE, they provide sliding abutment surfaces for the conveyor belts and isolation from the copper coil.

This prototype was never built and the method was never implemented at the Barrick Valedero mine due to ongoing ecological and geo-political problems at the mine site in Argentina and the lower price of gold at that time.