Hemp Decorticator, Scutcher & Hackler, Model SDS-60

SDS-60 Aggressively breaks Lignin Bonds in Hemp Fiber with 3D Differential Shearing.

Inquiries welcome. Full engineering shop drawings including with a non-exclusive IP license All Rights Reserved, ca: 2022

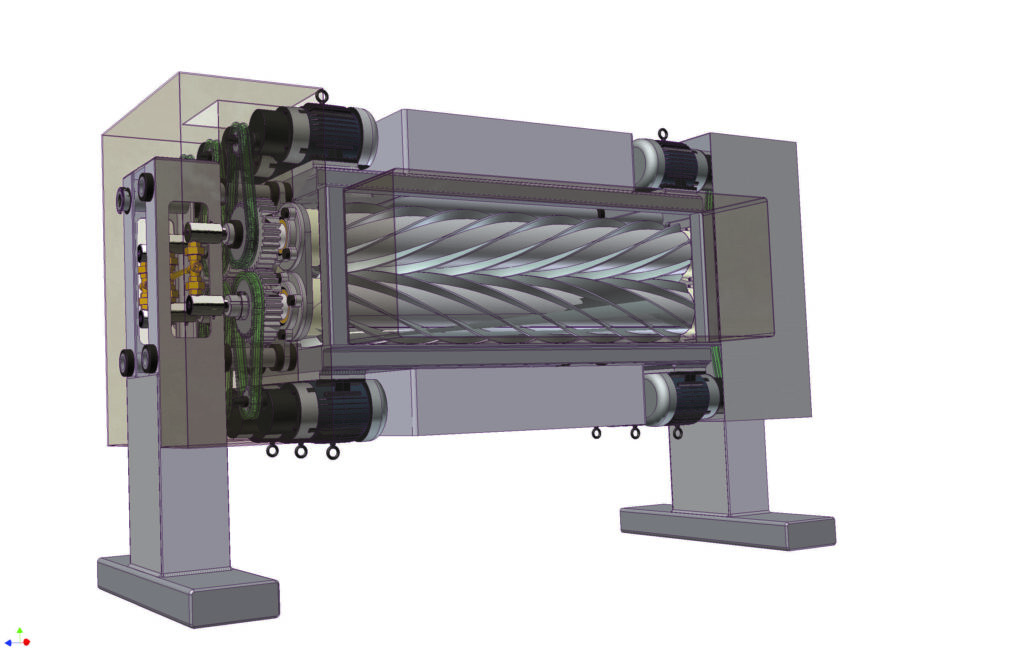

True 3D Differential Shearing of hemp stalks provides the traditional decortication, scutching and hackling in a single machine.

Rotary Air Unions on each roller allows cooling air through them as they spin in real time.

Dangerous heat under load is thus abated in process with compressed air flowing through the rollers keeping them under the ignition temperature of hemp fiber.

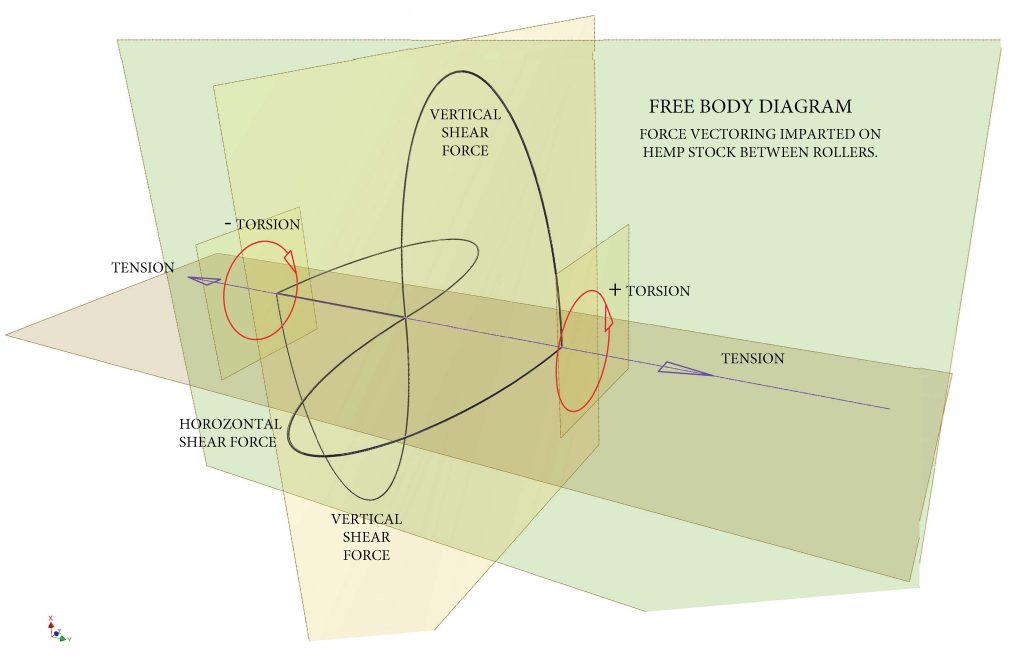

60 HP powers six helically splined rollers with each vertical pair spinning at 200, 300 and 400 RPM thus providing the RPM differentials needed to load the entrained hemp fibers as shown in the free body diagram below. The power requirement is divided by 12 gearmotors rather than a single gearmotor.

Helical Splined Rollers. 60″ long x 10″ Dia. are forced air cooled keeping temperatures below the ignition point of the hemp biomass before ejection at velocities of 100 ft / sec. or better. A throughput of 1 ton / hour is a conservative estimate depending on biomass moisture content.

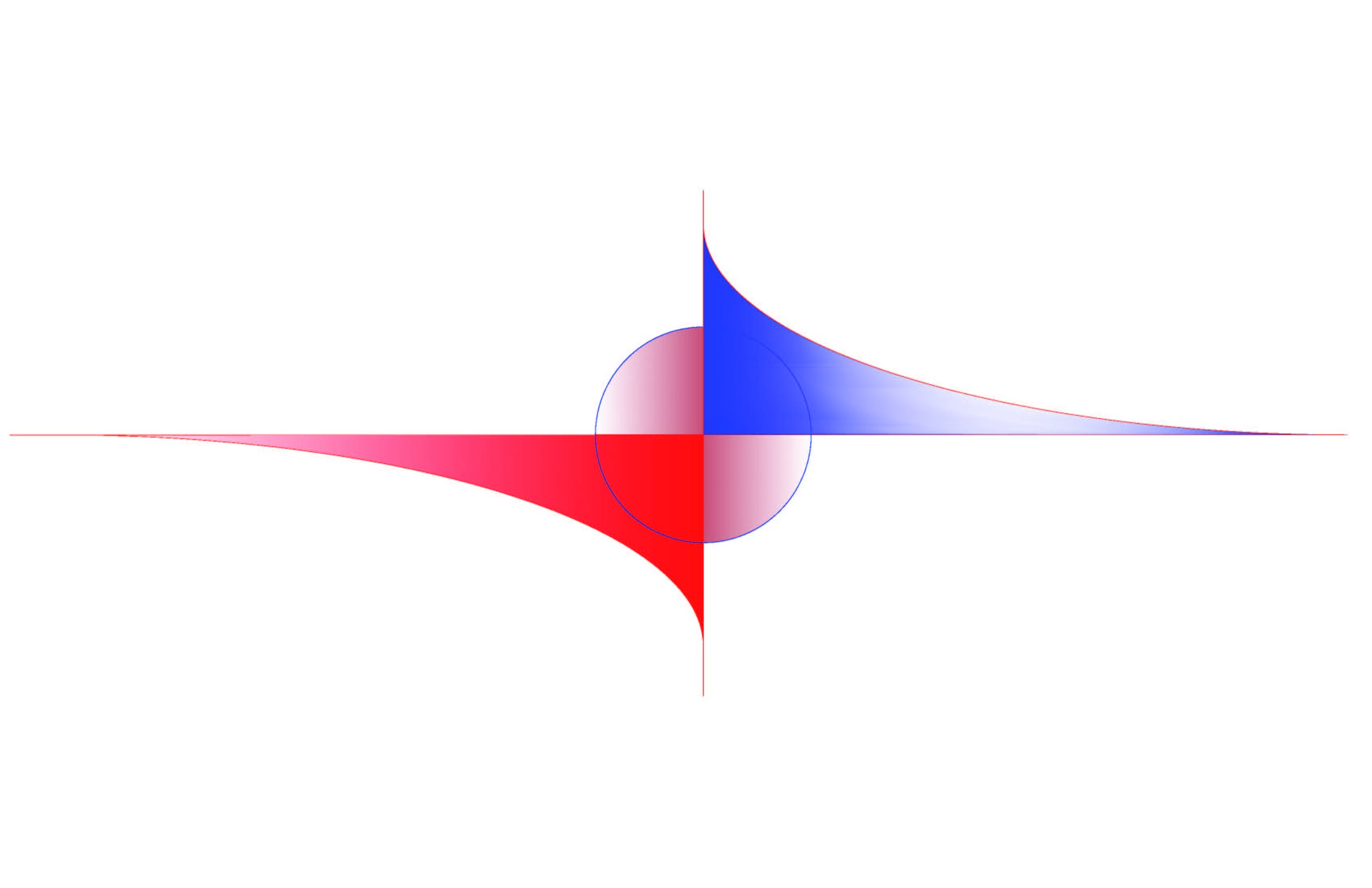

These curves represent the magnitudes of the forces imparted to the hemp stalks as they pass through the array of helical rollers. The helical flutes on the rollers mesh together to provide positive gripping and shearing forces to the hemp stalk morphology with passage through the process.

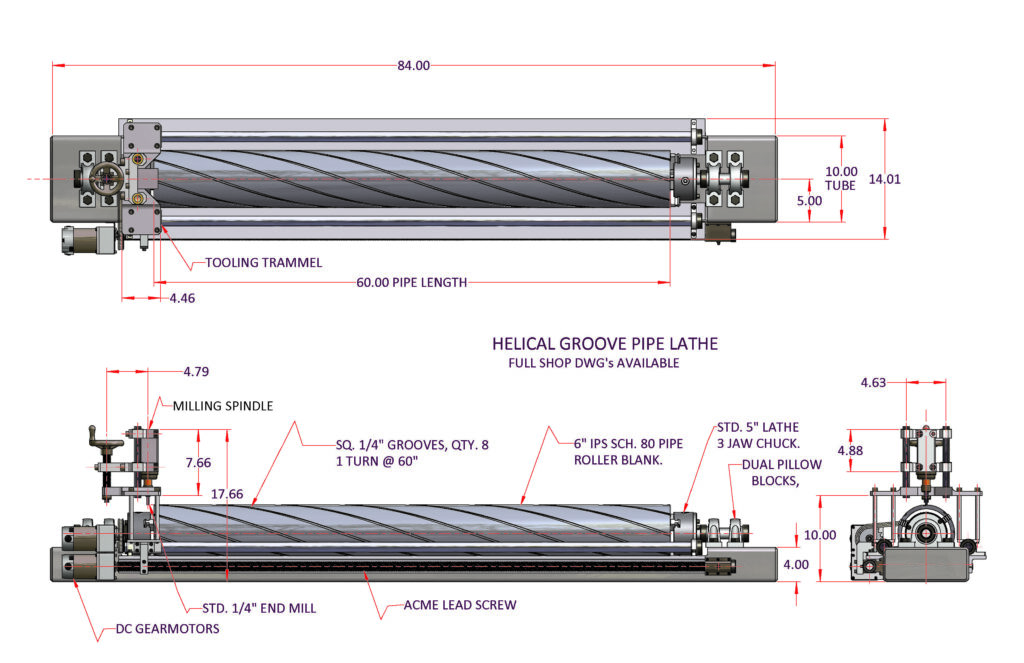

The helically splined rotors are fabricated with our unique lathe tooling fixture as welded assemblies previously not thought possible without CNC machining from a solid billet.

The helical splines are fitted and welded to the compound curve surface of machined helical grooves into the pipe with 1.25″ x 0.25 flat bar.

CNC machining these splined rotors out of solid bar stock is horrendously expensive, so we have designed a lathe tooling fixture allowing using standard sch. 80 6″ IPS Pipe up to 60″

The 12 AC motors are 3 phase 575 VAC 5 HP @ 1800 RPM each driving a Boston reduction gearbox, then a 1:2 Roller Chain Drive Reduction thereafter delivering up to 50 HP if called upon. A 60 HP diesel generator for field use would be adequate, or 575 VAC @ 80A service indoors.

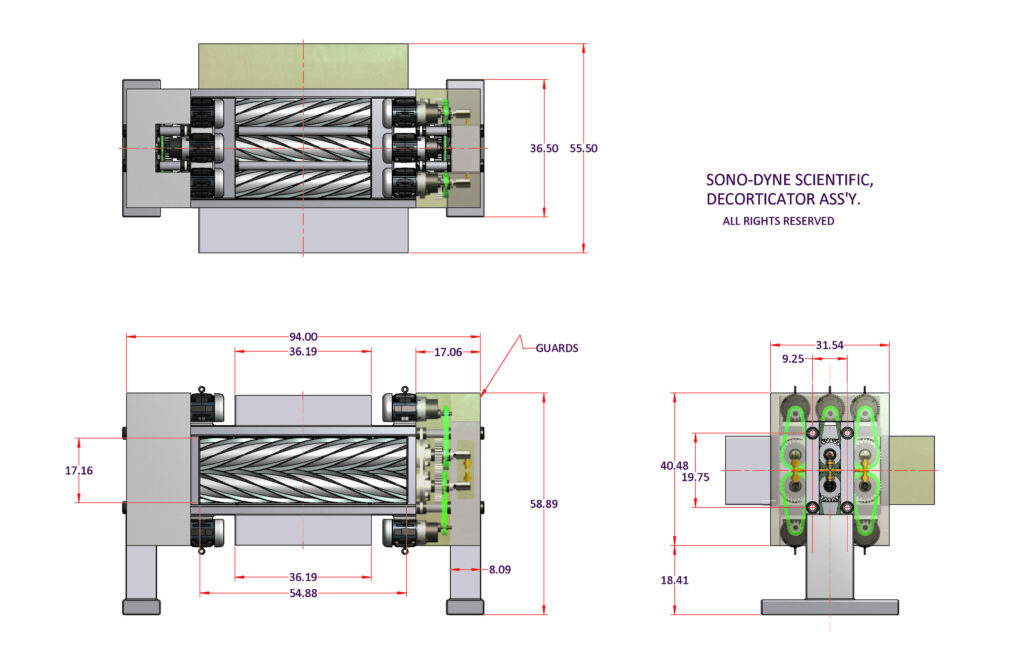

Specifications

Approximate Mfg. Cost and Commissioning = $150k U.S.

Weight; 6,600 lbs.

Power: 60 HP 575 VAC @ 80A Outside Dimensions: 94″ x 55″ x 58″

Throughput: 2 to 5T / Hr. moisture content dependent.

The Helical Roller assembly fixture consists of a custom made lathe with provisions of transferring helical geometry onto the surface of a length of pipe to which a standard end mill cutter spindle head follows said geometry in both directions

The end mill cuts a 1/4″ square helical groove into the pipe wall.in two passes, then indexes a rotation to the pipe for the next groove position and repeats the cut. This sequence is repeated for any number of grooves.

Once the pipe is chucked up securely, the cutting sequence for the entire roller pipe is automated from start to finish and will enable welding the flat bar into the grooves while the pipe is still held between the two chucks.

The control logic is provided by a pair of VFD’s and some outboard relay ladder logic for the operator controls and prompts.

This fabrication fixture for making the helical splined rollers is an investment for those planning to manufacture this equipment.

Full fabrication documentation for this tooling fixture with electrical controls is available with IP license.

Otherwise the only other viable way of making these is via CNC machining out of a solid billet or block of steel which is horrendously expensive and wasteful in material and time.