High Viscosity Mixing & Blending for Large Scale 3D Printing.

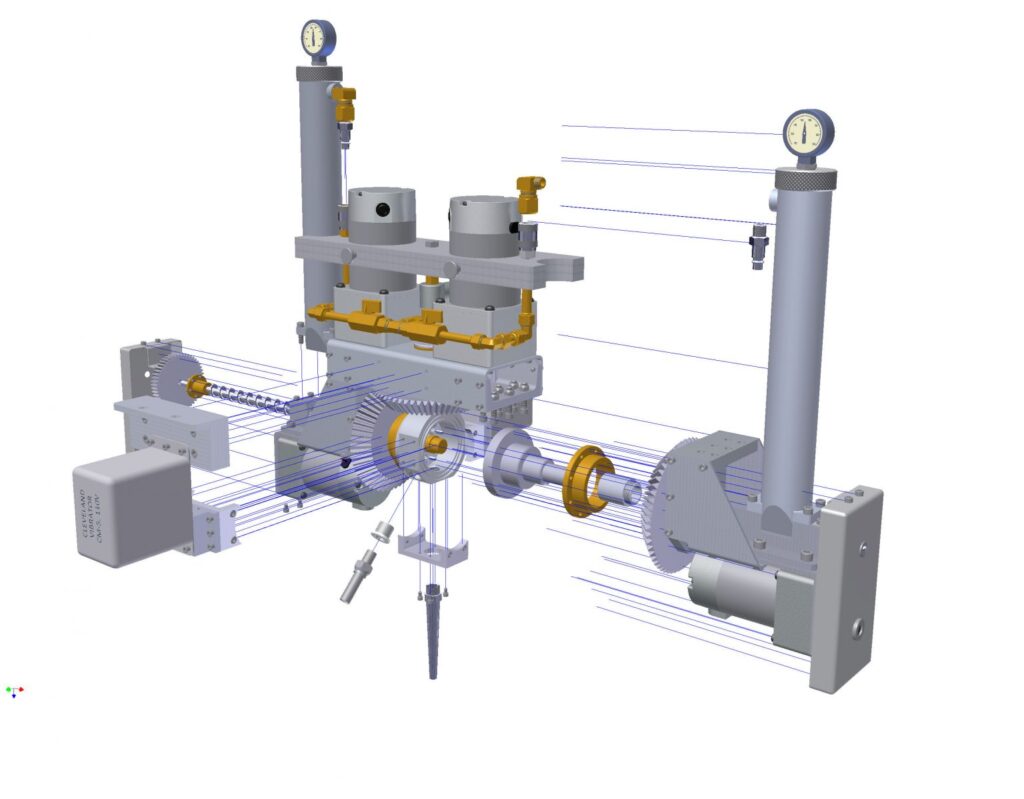

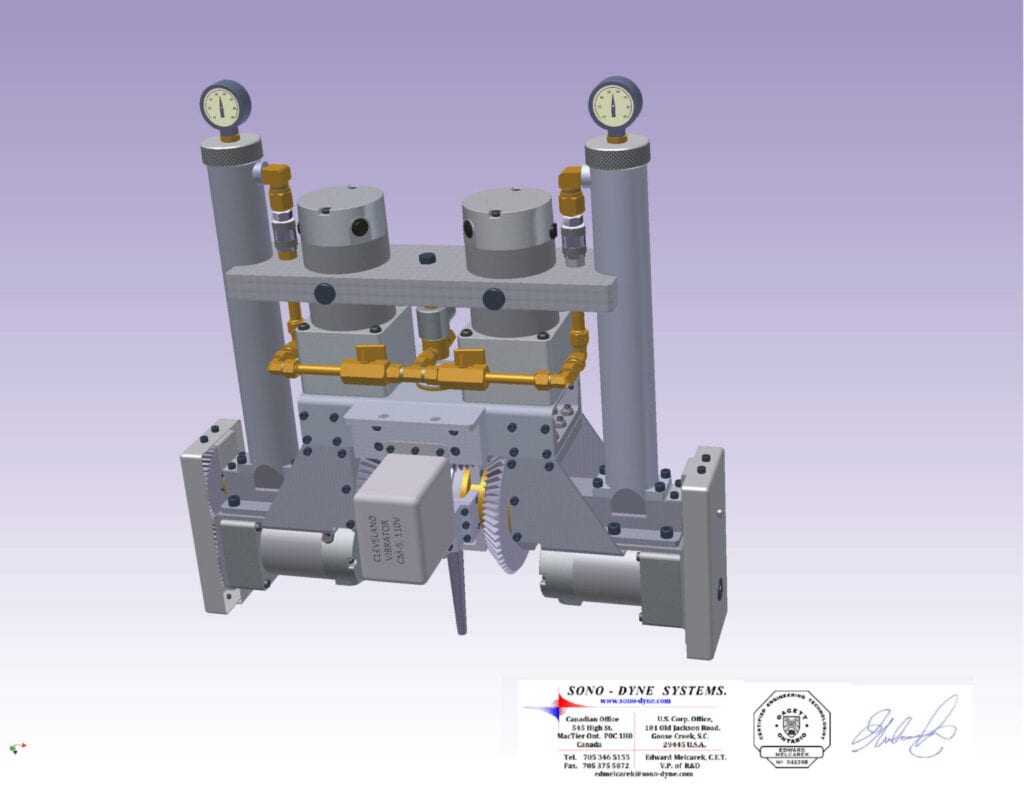

This Compact and Modular equipment can be integrated into any existing process line that needs to blend two highly viscous materials.

The two tubular magazines holding the viscous materials to be blended are air pressurized from above to provide a constant feed stock force into the two supply augers.

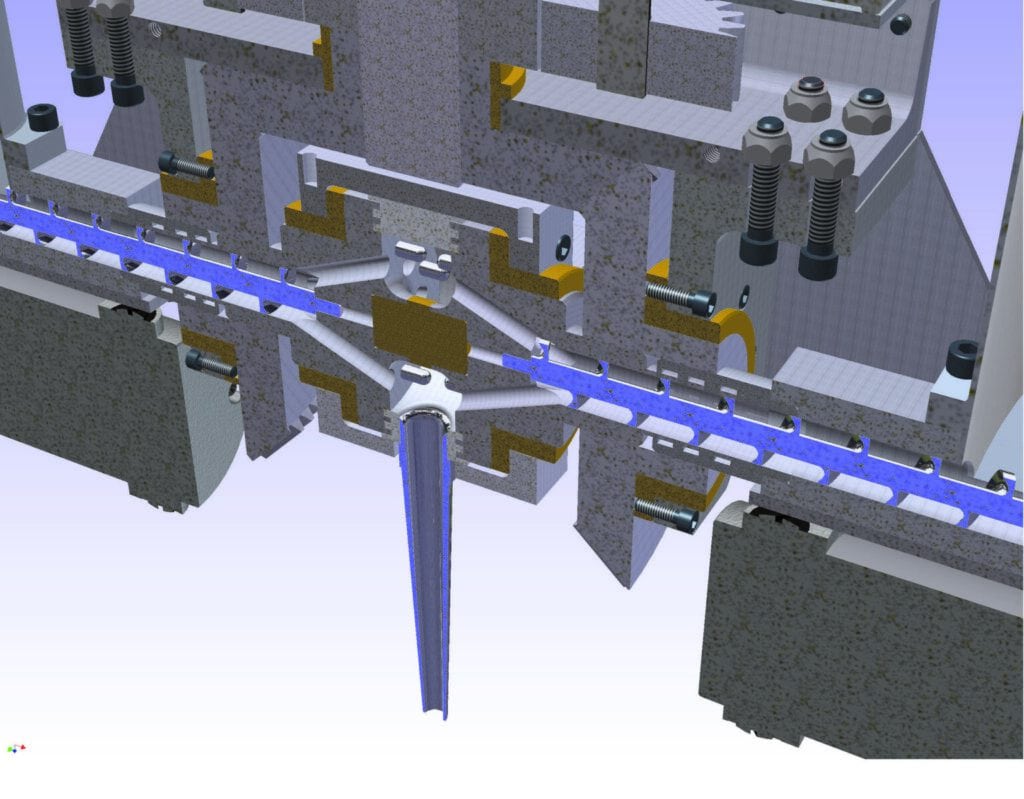

The mixing of highly viscous materials is made possible with a pair of counter-rotating mandrel extruders that are fed coaxially. Blending occurs in the chamber between the two extruders rotating in opposite directions.

The two extruders themselves however, rotate at the same RPM and the two augers rotate at different rates to provide a blend differential.

Material is fed into the rotary extruders with augers on each side that are driven to generate any volumetric ratio of materials that are to be blended.

Aggressively applied high shearing forces are generated by the steel dowels attached to the counter-rotating extruders.

The blended material is ejected under pressure through the nozzle connected to the stationary mixing chamber.