Induction Heated Biochar Production at Utopia Hemp.

Model UH- 1 Coaxial Rotary Biochar Kiln.

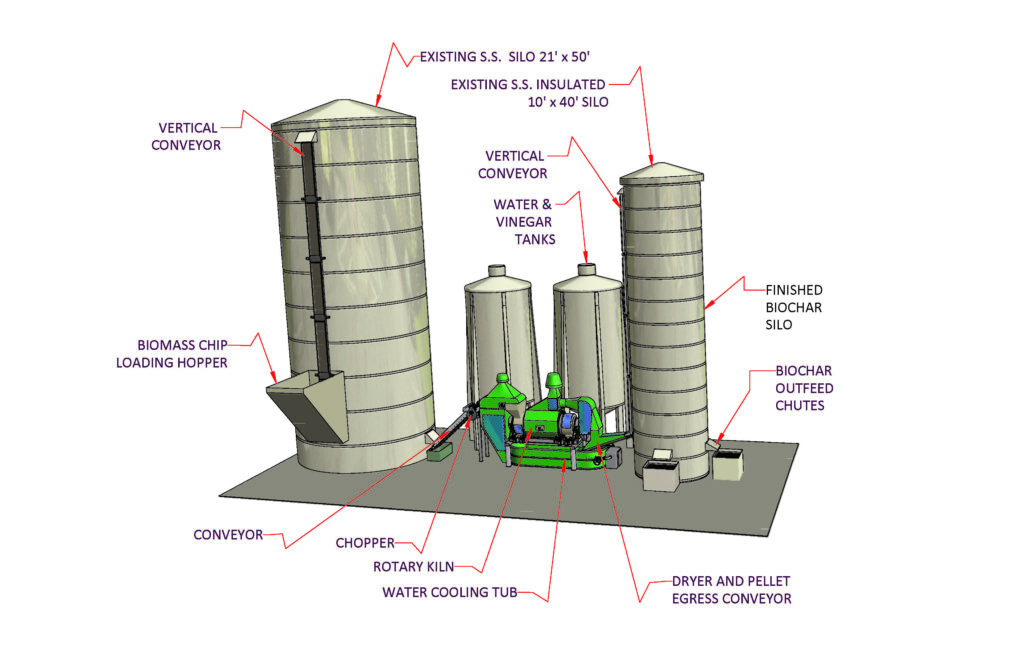

Raw hemp chips are chopped to a uniform and consistent size prior to entering the chip storage hopper.

They are conveyed into the kiln by means of rotating auger flights and pyrolized at high temperature between them.

The hot biochar pellets are expelled into a flowing water bath contained in an oval tank wherein a partially submerged metal screen belt conveyor scoops out the wet biochar pellets as they approach.

Now they are air dried as they move to the holding silo or gaylord storage bin.

Oxygen-free Pyrolytic Heating is entrained and captured between the flights of an auger moving the biomass along an induction heated cylindrical surface. A heat gradient in the center of the cylinder wall is generated without flame or combustion gases by means of an induction coil that is positioned around the coaxial center of a rotating cylindrical steel drum.

All Rights Reserved ca. 2023 with partners at Utopia Hemp Inc. Tom Smith CEO

Induction heating of the cylinder walls controls the pyrolysis temperature ( 950 deg C ) to within 20 degrees Celsius of any selected temperature for any biomass in process and the residence time at temperature is controlled with our unique and novel Auger Plenum Transport System. The inside surface geometry between the flights and drum wall will generate spheroidal nodules about the size of a BB.

Major Features and Attributes;

- Creosote vapors (Soot) egress and accretion in Wet Precipitation on removable accretion plates.

- Variable pyrolysis temperatures, precise control thereof.

- No hydrocarbon fuels needed, all electric power to 10 kVa.

- Variable speed differentials between the auger and drum for residence time and Biochar pellet size.

- In-Line Biomass Chopper at Infeed Hopper ensures uniform particle sizes

- Water bath biochar immersion cooling provides excellent single short step heat transfer.

- Variable pellet size is achievable via internal transport surface geometry and feed speeds.

Utopia Hemp Ltd. job-site.

This pending installation has existing storage silos already in place and are in working order.