PFAS Commercial Scale Water Scrubbing System.

Fluorine-Carbon Bonds in PFAS have been successfully broken in our lab making Hydrogen Fluoride then Calcium Fluoride by-product in a second stage. Electrically Charged Vibrating Carbonic Disc Electrodes generate sufficient energy at points of contact with waterborne PFAS particles breaking the Fluorine-Carbon bonds instantly in water during electrolysis. This includes AFFF. ( USPTO provisional filing date granted )

Under development is our scalable 100 Gal / Hr. pilot system comprising Electrolysis Modules and our subsequent Calcium Hydroxide Neutralizer / Fuel Cell stage where we reclaim electrical power and remove the filtered solid by-products simultaneously.

All Inquiries are welcome. ( All rights reserved ) Seeking Partners

.

It was found that vibratory energy was needed to generate a response in the detection of hydrogen fluoride which is the chemical marker that carbon fluorine molecular cleavage has occurred within the Teflon tape ( PFAS ) test sample surface.

Sensorex HF-10 Sensor response to Hydrogen Fluoride from Teflon tape (PFAS) wound around graphite disc electrode perimeter..

One will notice the voltage on the meter “bumping up” in increments of millivolts, where 4 mV = 1 ppm of hydrogen fluoride.

A prior version (right) used graphite rod electrodes and higher voltages with negative results. It was found greater surface area and acoustic vibration significantly improved reactivity with the water. The Hydrogen Fluoride response from the Teflon tape (PFAS) was observed up to 10 ppm with the graphite discs acoustically driven by piezo-electric elements at 9.3 kHz.

USPTO Provisional Filing Date Granted.

It makes little sense streaming away the H + OH radicals taking energy to make from the water electrolysis in order to neutralize a few ppm of PFAS in the subject water.

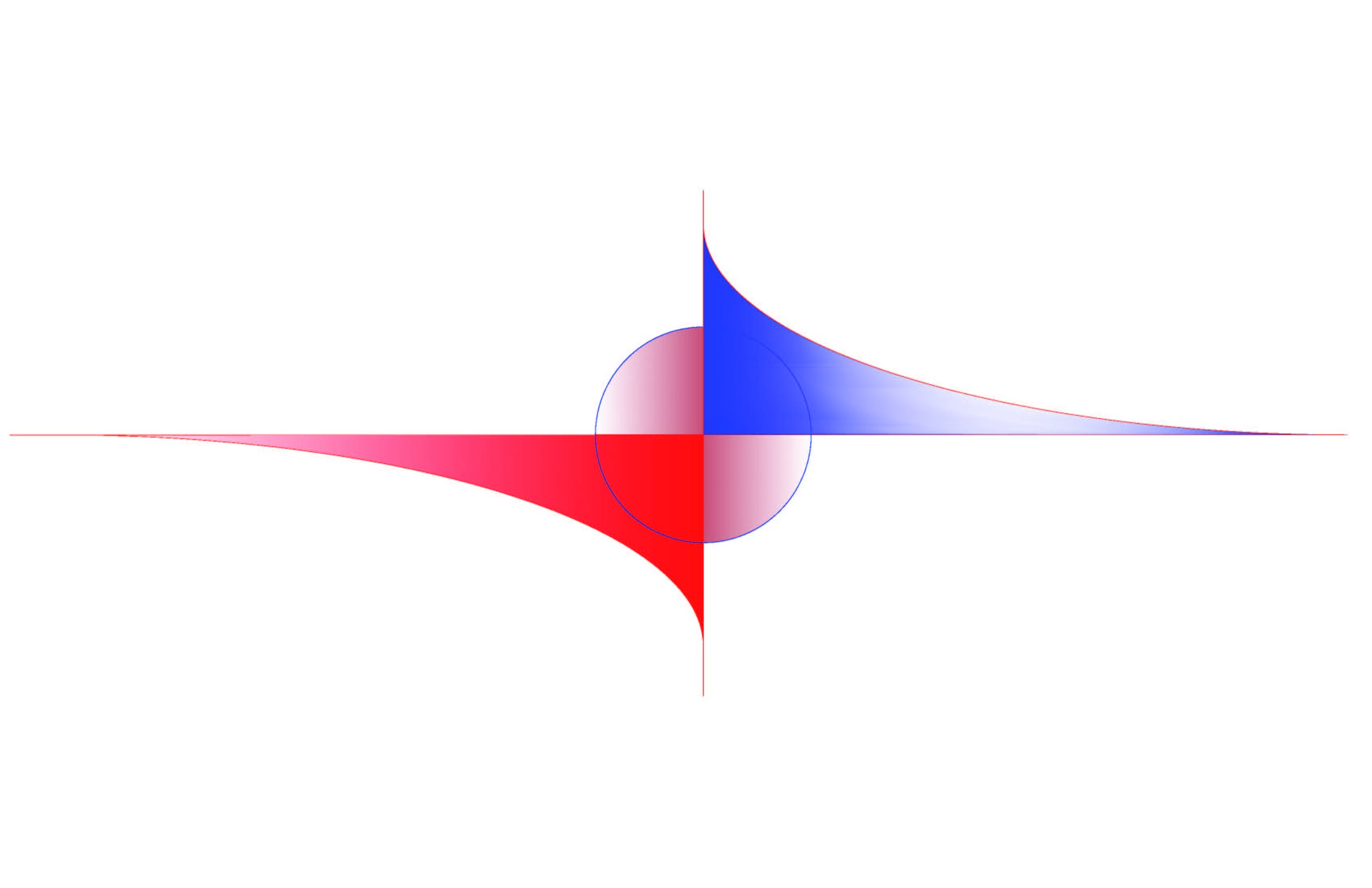

The system is economically viable energy wise if configured shown here with the recovery of electrical energy expended in the water electrolysis..

In conjunction with neutralizing the HF acid and Carbonic acid generated in the first stage reaction with the carbon electrodes, the concentration of hydroxide electrolyte is adequate to allow a voltage to develop between the electrodes

Thus, the hydroxide based fuel cell recovers the electrical energy spent in making OH + H radicals from the water electrolysis and stores that energy in conventional lead acid auto batteries.